Subsea Ball Flanges & Swivel Flanges, Subsea Barred Tees, Subsea Pigable Wyes...

We are particularly proud to be renowned as a reliable and dynamic partner in supply of outlet fittings, special flanges, connectors and special forged pieces.

All single items of we supply are monitored by an accurate Quality control planning. A team of qualified experts is able to supply calculation according to the main recognized codes and standards like ASME, DIN, EN and Stoomwezen requirements.

The quality level of all products is guaranteed by a complete internal quality plan and certificating under ISO-9001, TüV (according to AD 2000-Merkblatt W0/TRD100), API, PED (accordance with Pressure Equipment Directive 97/23/EC), Burst test (Det Norske Veritas), and certainly Lloyds and Stoomwezen

The Subsea Ball Flange Connectors

The Subsea Ball Flange Connector connects directly to a mating RTJ flange while accommodating pipeline misalignment angles for an unstressed tie-in connection.

- Angular adjustment of ±15° (30° included angle)

- Bolt hole rotation feature.

- Repeatable, integral metal-to-metal seal.

- Annulus test port and seal test feature.

- Enhanced wiper seal system to isolate the metal seal area from contaminants.

- Designed to accommodate high-capacity flange spreader loading.

- Stocks our misalignment connectors 4” thru 60”size range to meet our clients rapid response needs.

The Subsea Swivel Ring Flanges

The Subsea Swivel Ring Flanges provide a bolt hole alignment feature to simplify subsea pipeline tie-ins.

- ASME Sec VIII, Div 1 compliant.

- High-strength hub material & removable retainer ring.

- Equivalent-strength weld bevel design.

- Rule-based design method insures consistent design execution and rapid development for unique applications.

- Inventory for fast delivery - 2" thru 30".

DESIGN FEATURES AND BENEFITS

The swivel ring flange utilizes a spring steel retainer ring to capture the rotating flange component of the connectors. This feature eliminates welded retainers and permits the removal of the retainer ring. The removal retainer ring feature makes it possible to clean and lubricate the swivel ring interface between the hub and flange after fabrication and coating to assure easy rotation during installation.

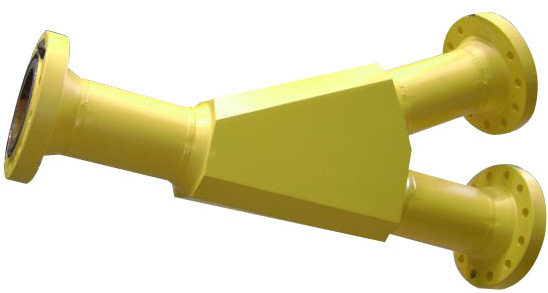

The Subsea Piggable Wyes

The Piggable Wye is a “Y” shaped pipeline fitting designed to facilitate the pigging and cleaning of lateral subsea pipeline systems. The Wye can be manufactured from single carbon steel forging or casting.

There are two pipe inlets, each configured at an angle of 15 degrees from the center line of the fitting for a 30 degree angle of entry between the two inlets. ASME compliant design

We offer the Wye in a standard welded (WE x WE x WE) configuration. Both designs readily accept all standard pipeline pigs, including cup and disc type models used for cleaning of the pipe’s internal bore.

We can provide the fabrication services to weld customer provided pipe pups to the weld ends of the wye as an additional option upon the customer’s request.

The design of each wye is subjected to a full Finite Element Analysis to verify the design integrity prior to manufacture. Additional testing or different configurations can be provided at customer’s request. ASME compliant design

The Subsea Piggable Wyes

The Subsea Piggable Wye provide the operator with means to use cleaning pigs and smart pigs in two converging pipelines.

- ASME Sec VIII, Div 2 compliant design.

- FEA design review performed in-house.

- Symmetric and asymmetric designs available.

- Forged or cast low-alloy steel construction, depending on size.

- Customer-provided pipe pups shop welded to simplify field welding.

- Fully hydrotested and bevel prepped for installation prior to shipment.